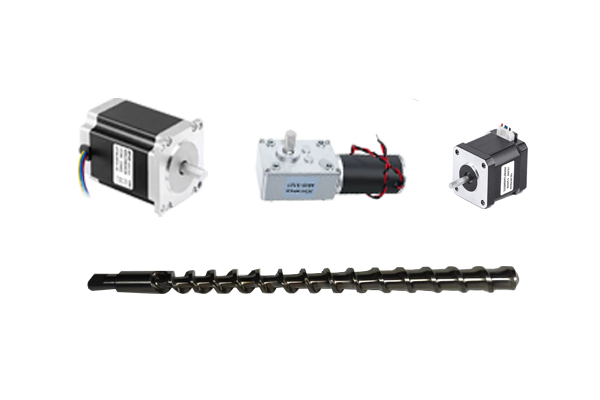

Core Construction: Precision-Selected Materials, Zero Compromises

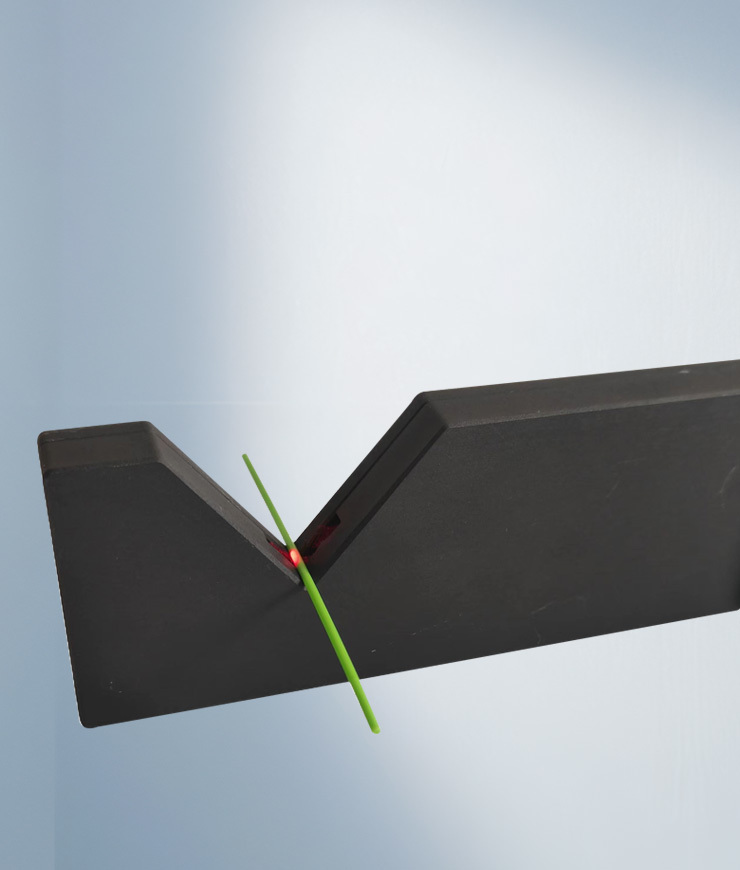

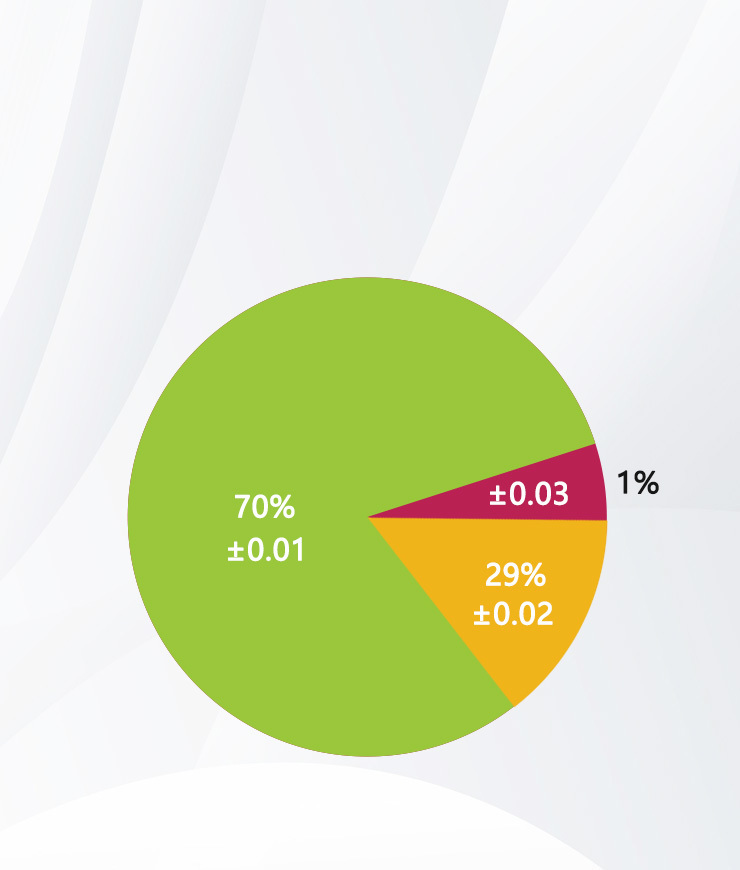

Raw material production line diameter display

Eco-Friendly Material Development

01

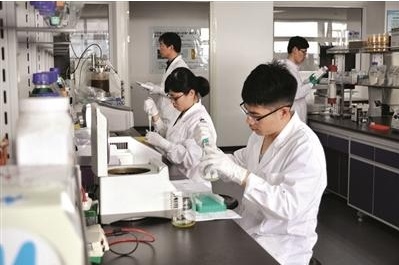

Expertise in degradable and sustainable materials, with extensive experience in material modification and R&D.

02

Continuously introducing new eco-friendly materials, such as bio-based PLA and PHA, driving the green transformation of the 3D printing industry.

03

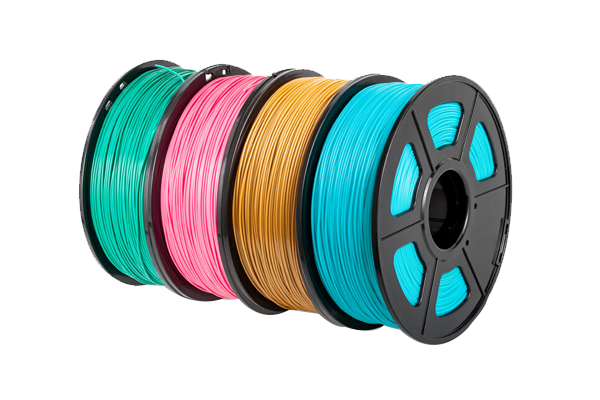

Regularly stock high-quality raw materials in the latest colors/specifications according to your needs, bringing you the best 3D printing experience

What can C1 do for you?

The C1 desktop extruder is designed to meet the demands of high-volume 3D printing environments. With a maximum output of 400g/hour, it can seamlessly supply filament to 10 or more 3D printers running at full speed.Relentless Reliability: 7×24 operation

Custom High-Precision Filament

Create filaments with custom colors, and materials, Creating unlimited possibilities

Waste Recycling

Recycle all 3D printing waste (finished/failed prints, supports, Brim、skirts)

Material R&D

Conduct blending experiments

Develop innovative composites and functional filaments

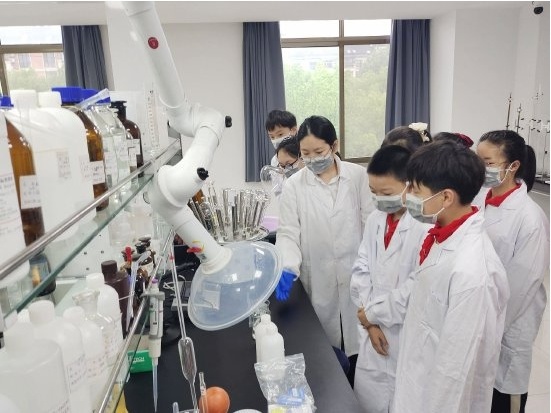

Professional Use

Aerospace: Small-batch high-strength specialty filaments,Medical/Education: Biocompatible or educational materials

Video Display

C1's outstanding performance can withstand any test

PLA filament make 2

PLA filament make

PETG filament make

Waste recycling